Bioenergy Devco hearing on permits is Oct. 26

Bioenergy Devco has crossed several hurdles in its effort to construct the first anaerobic digester poultry waste processing facility in the region. Now, the company is in the process of getting permits approved from the Delaware Department of Natural Resources and Environmental Control.

A virtual public hearing on the permits has been scheduled for 6 p.m., Wednesday, Oct. 26. Prior to that hearing, on Sept. 28 DNREC staff held a virtual information workshop logged on to by nearly 100 people.

“This was an information session. It's not part of the formal public hearing. It's not part of the public record,” said DNREC Deputy Secretary Lisa Borin Ogden.

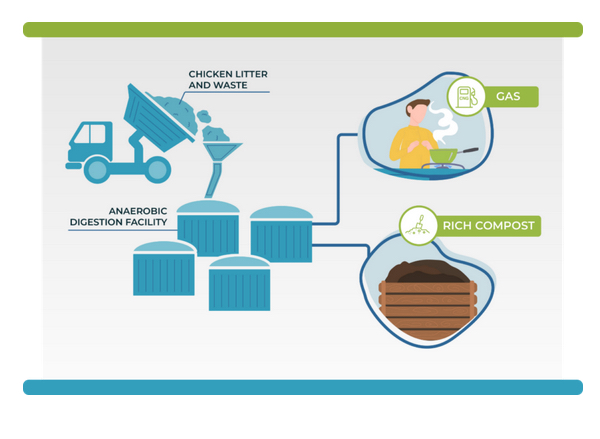

Poultry waste recycling

Sussex County Council approved a conditional-use application in April 2021 filed by Bioenergy Devco, based in Annapolis, Md., to amend four other conditional-use permits issued over the past three decades for the project to convert poultry waste into natural gas and compost using an anaerobic digester process at its Bioenergy Innovation Center facility south of Seaford off Route 13A.

The facility has filed for permits to allow recycling of up to 250,000 tons per year of poultry litter, consisting of manure and bedding from cleaned out poultry houses, hatchery waste, including egg shells, and DAF cake and DAF sludge. Poultry litter will make up 10% to 15% of the waste.

DAF, or dissolved air flotation, is the liquid byproduct left the wastewater treatment process for poultry processing. Suspended solids are removed with the use of air bubble flotation. Air is dissolved into the water and mixed with the waste.

Peter Ettinger, Devco chief strategy officer, said about 80 percent of the waste would be DAF. During the presentation he noted that the facility accepts the same poultry waste for its current composting operation. The company is currently permitted to sell 30,000 tons of compost each year made from poultry waste.

The company would continue to operate its current composting facility and add the soil amendment from the anaerobic process to the compost.

Ettinger said the facility would accept poultry waste that would otherwise end up in landfills, incinerated or be applied on land. He said other benefits include reduction of odor with all organics in sealed tanks, the production of a renewable natural energy, reduction of greenhouse gases with the capture of methane gases and the creation of a high-nutrient, non-fossil fuel soil product.

Under the plan, up to 60,000 gallons per day of pre-treated wastewater would be trucked to the Seaford wastewater treatment plant for disposal. Ettinger said some of the recycled water would be used in the process. The company also has a permit filed for construction of an on-site pre-treatment facility.

Testing was an issue that generated several questions. Devco staff said DNREC permits require pre-process testing of all materials brought to the facility.

Jeff Deats, facility manager and director of operations and maintenance, said all compost is tested before it can be sold.

Permitting process

The company has already had a conditional-use approved by Sussex Country, received an entrance permit from Delaware Department of Transportation, an approved fire protection plan from the State Fire Marshal's Office and an approved sediment and stormwater plan from Sussex Conservation District.

Pending permits are being evaluated by DNREC's division of air quality, water and waste and hazardous substances. The company has an approved permit for its composting operation and a new permit would be considered an extension of the existing permit.

Ettinger said it’s anticipated that DNREC will issue its findings on the permits by February 2023.

How many trucks?

Questions covered a wide gamut from testing to truck traffic, from storage of natural gas to community outreach and the compost market.

Maria Payan said the roads around the facility are not designed for heavy industrial use. “How many trucks will be and out?” she asked.

Ettinger answered that there would be 111 trucks a day into the facility during business hours, which is a less than 2 percent increase from current traffic.

Terri Dykstra also asked about truck traffic. “Has there been a study on the impact of this traffic on the nearby community?” she asked.

Ettinger said the anticipated truck traffic is not enough to warrant a traffic impact study, according to DelDOT requirements. He said there are 4,000 trucks on the roads – Route 13 and Route 13A – in the area each day. He said some of those trucks are transporting poultry waste already to out-of-state landfills.

Eul Lee pressed the presenters to provide more specifics. Ettinger said there would be four gas trucks and 10 trucks transporting wastewater to the Seaford wastewater treatment plant and the rest would be trucks hauling in poultry waste for processing each day.

Ettinger emphasized that poultry waste off the Delmarva Peninsula would not be transported to the site.

“This facility has been in operation for a couple decades with truck traffic. It's not a new impact and DelDOT did not require more information,” said consultant Jeff Bross.

Concerns about community

Dykstra also expressed concerns with the impact on a nearby Haitian community.

“This community will be impacted. You need to communicate with them and offer them tours. I want to know how they feel about this,” Dykstra said.

Ettinger said the community is one mile away and is separated by a forest from the property. He said his staff would reach out to the community for input and would offer tours. In addition, he said, the company's presentation will include versions in Spanish and Haitian Creole.

Dykstra also asked about the flare as part of the biogas operation. Ettinger said the flare would be 30-feet tall but only used in case of an emergency.

When asked about an environmental impact study, consultant David Small with Duffield Associates said the waste and hazardous substances permit requires environmental and hydrological assessments and groundwater sampling.

Concerning noise, Ettinger said the facility is only using 11 acres of the more than 200-acre site with wide buffer areas. “Everything is enclosed and there will be no more noise than a normal farming operation,” he said.

Testing was another issue that generated several questions. Devco staff said DNREC permits require pre-process testing of all materials brought to the facility.

Biogas and market questions

Willie Scott asked several questions about the planned biogas operation. Ettinger said no natural gas would be stored at the site and it would be compressed and pumped into trucks and transported off site or directly added to the gas line.

Payan said there would be no market for the facility's compost. “Where will this digestate compost end up? Will it end up as waste on fields in the area? Do you have signed contracts to handle 250,000 tons a year?” he asked.

Deats said, “There are markets and we've been sold out multiple times this and last year,” he said, referring to the existing composting facility. “There is no shortage of demand for our product.”

Deats said the compost is used by companies on the Eastern Shore and throughout the region. He added that every batch of compost must be tested by a third-party laboratory.

How the process works

The plan is to repurpose the former pelletizing plant with upgrades, including enclosed poultry waste recycling and shipping areas, an odor control system and control room. The facility will consist of a four anaerobic digesters, pre-treatment tanks, a biogas processing area and wastewater pre-treatment operation.

The company purchased the existing composting plant in February 2020 for $15 million from Perdue Farms.

In the anaerobic process, poultry waste in the digesters is heated and constantly mixed for about 30 days. Microorganisms break down the material, which is called digestate. A centrifuge will remove excess water from the digestate, with the remaining solid material transferred to the composting facility. There it would be processed with wood waste to make organic compost.

The microorganisms release biogas, which is a mixture of methane, carbon dioxide, water vapor, and traces of hydrogen sulfide and ammonia. The gas will be captured and scrubbed as part of the facility's process.

Chesapeake Utilities will take the biogas off site, clean it to renewable natural gas and inject it into the company's natural gas pipeline.

Ettinger said the plant would operate from 7 a.m. to 7 p.m. Monday to Friday, and 7 a.m. to 1 p.m. Saturday. Ettinger said internal operations within the plant would be in operation seven days a week and the biogas system would be managed and monitored 24 hours a day.

The Sussex County facility will be the company’s first in Delaware and its fourth project in the United States since joining forces with Italy-based BTS Biogas to enter the United States market. In Europe, anaerobic digesters – large and small – have become an accepted method to recycle organic waste. Ettinger said Germany alone has 9,000 digesters.

Written comments are being accepted through Friday, Dec. 2, at de.gov/dnreccomments or DNRECHearingComments@delaware.gov. Those wanting to speak at the Oct. 26 public hearing must pre-register by noon the day of the hearing at de.gov/dnrechearings.