Bioenergy reveals plans for recycling facility

Bioenergy Devco unveiled plans to construct a first-of-its-kind poultry waste recycling plant in the region at its composting facility near Seaford during a Feb. 11 Sussex County Planning and Zoning Commission public hearing.

The company, which purchased the existing plant off Route 13A south of Blades and Seaford last February from Perdue Farms, has filed a conditional-use request to amend four other conditional-use permits issued over the past three decades for the project to convert poultry processing plant waste, known as DAF, into natural gas and compost using an anaerobic digester process.

In addition, it's estimated the plant will recover 90 million cubic feet of carbon dioxide per year for resale to customers.

DAF, or dissolved air flotation, is the liquified end product of wastewater treatment at poultry processing plants. Bioenergy has entered into a 20-year contract with Perdue to accept its processing plant waste.

Sussex County Planning and Zoning Director Jamie Whitehouse said 113 letters and emails in opposition and 10 letters and emails in support are on file in the public record.

Several people testified via telephone against the application citing environmental issues, concerns with truck traffic, the change in use of the property to a heavy industrial use and confusion over what was included in the application.

After the hearing, the commission voted to defer a decision to a future meeting. The application was included on the commission's Thursday, Feb. 25 agenda.

Sussex County Council will have a public hearing on the application at 10 a.m., Tuesday, March 16, at the Carter Partnership Center at Delaware Technical Community College in Georgetown.

Treatment of plant waste

Anaerobic digesters use a natural process driven by microorganisms to process organic materials in a closed system, which transforms organics to renewable natural gas, as well as an organic soil amendment or compost for farmers and gardeners.

“This is not waste but an opportunity to create two new products,” said Peter Ettinger, Bioenergy chief development officer. “What's good for the environment is also good for business. They can work hand in hand.”

By recycling the poultry waste, Ettinger said, land application is eliminated and a new source of natural gas is created.

A DNREC permit would allow up to 220,000 tons of DAF per year to be recycled at the plant.

“How will this help farmers if it's DAF and not litter?” asked Maria Payan of Selbyville during public testimony. “The waste which is not brought into Sussex County now will come in from Virginia and Maryland.”

She said land application of wastewater would still occur, which is not a benefit to Sussex County.

Jeff Bross, an engineer with Duffield Associates, said to call the anaerobic digester process a pollution-creating activity is disingenuous. “You can only get permits when you are not polluting and not a danger to residents. DNREC is a very rigorous review agency. This is a self-contained improvement to the composting process,” he said.

Compost and natural gas

In the anaerobic process, poultry waste in the digesters is heated and constantly mixed for about 30 days. Microorganisms break down the material, which is called digestate. A centrifuge would be used to remove excess water from the digestate, with the remaining solid material transferred to the composting facility. There it would be processed with wood waste to make organic compost.

The microorganisms release biogas, which is a mixture of methane, carbon dioxide, water vapor, and traces of hydrogen sulfide and ammonia. The gas will be captured and scrubbed as part of the facility's process.

Chesapeake Utilities will take the biogas off site, clean it to renewable natural gas and inject it into the company's natural gas pipeline.

Commissioner Kim Hoey Stevenson asked what would happen to the poultry waste if it was not recycled at the proposed plant.

Ettinger said it would be applied on farm fields or stored in tanks – some in other states – for future land application on area farms.

Chris Bason, executive director of Delaware Center for the Inland Bays, said an anaerobic digester would be part of the solution for healthier water quality in Sussex County with three recycling plants in the area.

He said with CleanBay Renewables plants in Georgetown and Westover, Md., nearly half of the poultry litter produced on Delmarva would be recycled.

“It's a highly beneficial project but it should be closely inspected and regulated because of its close proximity to vital water resources,” Bason said.

He said regulations regarding stormwater runoff and air quality should go beyond minimum requirements.

“This is not a refinery,” said Dennis Schrader, the applicant's attorney. “It's environmentally sound and the process is good for the poultry industry.”

The attorney said a conditional-use approval would require that the applicant obtain all regulatory permits from state agencies to address environmental and traffic issues.

He said Sussex County Council has already approved a similar application for a poultry waste recycling plant (in August 2018). CleanBay Renewables will build a $60-million plant to recycle up to 90,000 tons of litter annually from poultry houses at a plant located off Route 113 south of Georgetown. The plant will convert the waste to electricity and fertilizer.

Plans for proposed plant

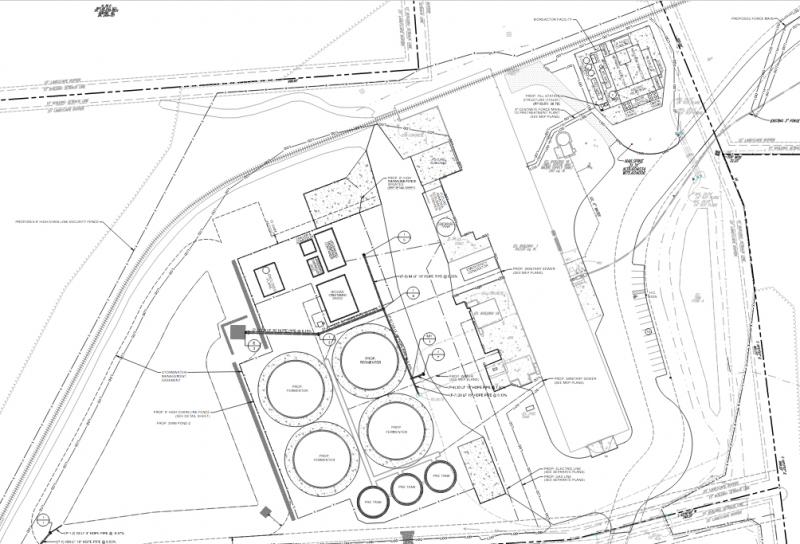

Duffield engineer Bross said the plan would be to repurpose the former Perdue pellet plant on 11 acres of the 228-acre parcel by combining the existing composting facility with an anaerobic digestion system. The existing building, no longer in use, would be enlarged from 69,120 square feet to 76,620 square feet.

Plans for the $40-$45 million plant include a 165,000-gallon equalization tank for the DAF slurry, which is about 10 percent solids and 90 percent water; four 1.3 million-gallon anaerobic digester tanks for DAF sludge and water; and two 1.3 million-gallon fermentation tanks. Plans also include a new wastewater pretreatment facility and an enlarged stormwater retention pond.

While most of the water used in the process from on-site wells will be recycled and used again, the plant would generate a maximum of 60,000 gallons of treated wastewater per day at full capacity. Bross said the current plan would be to transport the wastewater to a Sussex County facility for disposal. Ultimately, he said, discharge into a central sewer system would be the goal.

County engineer Hans Medlarz said the county has agreed to accept up to 30,000 gallons per day to be transported, pumped into a lagoon and sprayed at the Bridgeville spray-irrigation site if the company can meet all permit requirements. Because the Bridgeville plant is being shut down, the wastewater would need to be fully treated and not only pre-treated, Medlarz said. “This is not a long-term solution for them,” he said.

Confusion over application

Several people who testified against the proposed project said they were confused because the advertised application stated poultry litter, not DAF, would be used in the process.

Ettinger said the primary waste product used at the facility would be DAF from processing plants with small amounts of poultry litter from poultry houses. “We will look at a litter-based facility in our future,” he said.

The current composting operation processes DAF, DAF sludge and hatchery waste, not poultry house litter or manure.

Tyler Lobdell, staff attorney for Food & Water Watch based in Washington, D.C., said confusion about what waste product would be accepted at the plant could be like a blank check for any number of waste streams.

“Only DAF sludge is a contradiction to what they told the public,” Lobdell said.

“This is an area already overburdened with pollution,” he said. “This is a complete change in the use of the site, which warrants greater protections for the community. With a 20-year contract, residents would be locked in and it would further intrench factory farming.”

“This is no longer a farming composting exercise but the creation of a potentially explosive gas,” said Richard Steck of Milton.

Steck said the project should have been reviewed by state agencies during the Preliminary Land Use Service process to include information such as the specific amount of truck traffic and more information on the handling of compressed natural gas by Chesapeake Utilities. “I see a lot of holes in this application,” he said.

Traffic is anticipated to include about 45 trucks per day in and out of the plant, including trucks bringing in poultry waste and wood chips, and trucks leaving with compost and gas.

Litter and DAF

Litter – Mix of wood shavings and poultry waste removed from chicken houses

DAF – Liquified end product of wastewater treatment processing at poultry processing plants with about 10 percent solids and 90 percent water

About Bioenergy Devco

• Bioenergy Devco, based in Annapolis, Md., has developed more than 220 anaerobic digester plants in seven countries with four plants proposed in the United States.

• In 2020, Bioenergy sold 18,122 tons of compost. That’s an increase from the former annual average of 15,000 tons.