Ron Parks: Stained glass isn’t easy, but it’s rewarding

Ron Parks hadn’t intended on taking 11 years and 222 days to finish making his replica of a Tiffany lamp, but he did. There have been obstacles and life challenges, but there’s never been a loss of interest, he said.

The lamp, now prominently displayed on a desk in his living room, is a replica of a hanging dragonfly lamp designed by Louis Comfort Tiffany. It was a popular style, said Parks, pointing to all the fine soldering and tight cuts that were needed to complete the project.

Tiffany enjoyed nature and believed people should also be able to enjoy art at a reasonable price, said Parks, acknowledging that Tiffany stained-glass pieces still in existence are no longer valued at those everyone-can-enjoy prices.

Parks said he never forgot about the lamp, but family-related caregiving responsibilities and two jobs always seemed to push the project to the back burner.

“There was a series of deaths, and I just never got to it or couldn’t get to it,” he said.

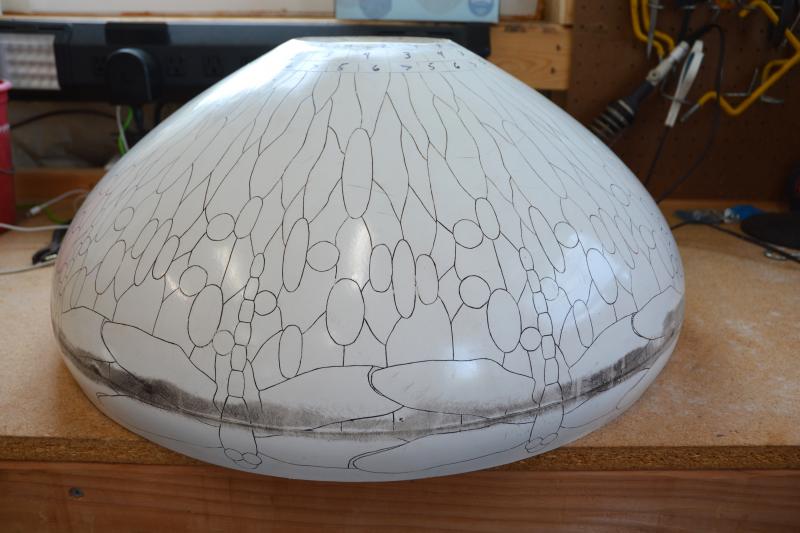

Finally, he said, one day his wife suggested he use glass that’s smooth on one side instead of textured. The Tiffany lamps use glass that’s textured on both sides, which makes it very difficult to make a smooth cut because the cutters don’t want to go in a straight line, said Parks.

“Once I bought the glass with a smooth back, I was on a mission to complete it,” said Parks.

A family member sparked Parks’ interest in stained glass while he was in college. He said that family member showed him what to do, and while the results were elementary, he said, it showed him the possibilities. Eventually, he signed up for a 10-week class to make the lamp with Hugh Archer, who consults with the Youghiogheny Art Glass Company in Connellsville, Pa.

“At the end of those 10 weeks, I was nowhere near done, but I had the techniques to keep moving forward,” said Parks.

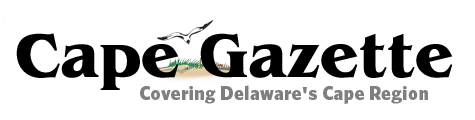

In some ways, making the lamp is like painting by numbers, but with glass. For this specific lamp, there’s a pattern that’s repeated nine times, which means a person cuts all the pieces of glass on that pattern nine times. There are 513 pieces of glass in total. The lamp is built on a mold from the top down.

Parks said the most difficult part of construction was the hanging dragonfly part because he had to do it by hand. The mold begins to curve in at its widest point. If he continued to use the mold, he said, it wouldn’t be able to come out.

Parks didn’t just spend more than a decade on this one piece. His house outside Rehoboth is full of his other pieces of stained-glass art. There are stained-glass pictures in the windows. There’s a band of angels on top of a bookshelf in his living room. Most of the rooms have at least one light fixture of some kind that has a stained-glass shade. There have been dozens of stained-glass figurines and pictures made for others.

The lamp was always there in the background to get done, but sometimes there was a need to just get a project done, he said.

“If it’s stained glass in this house, I made it,” he said.

Parks’ stained-glass workshop takes up about 100 square feet of a garage in his backyard. He’s got a table with supplies and tools that he uses to build on. There’s a light table where he cuts the glass. There’s a shelving unit with pieces of different colored glass.

Parks said there are three or four skills needed to make stained-glass art, but the work is in perfecting those three or four skills. It’s about getting faster and better, he said.

Pulling out a large piece from the shelves, Parks said among the difficult parts of using art glass is that the colors are not a solid shade of one specific color. He points to different sections where yellow is the dominant color in one area, green in another area or blue in another. He said the goal is to try to match up the colors as best as possible.

Parks uses the copper foil and soldering method created by Tiffany to connect the glass together. Prior to the use of copper foil, Parks said lead was used, which, besides its health issues, is heavy and pliable.

He will work on projects during the summer months, but he said the adhesive on the back of the foil doesn’t stick to the glass very well in the humidity, which means winter time is the best time of year. There’s a space heater that works pretty well, he said.

Parks said stained glass is a great hobby, but it’s not relaxing. It’s one that requires patience and time, he said.

“There’s always Band-Aids nearby,” he said. “Inevitably, you cut your hands. You go to wipe something away and there’s a little shard of glass that nicks you.”

On a tripod in the pool table room sits a blueprint of his next big project – a 45-inch-diameter stained-glass window that will eventually be installed at the Unitarian Universalists of Southern Delaware’s house of worship off Route 9, outside Lewes.

Currently, the blueprint is done in pencil, with a little bit of colored penciling added in certain places so he can begin to imagine what the window will look like when it’s completed. Parks said he doesn’t know how many pieces he’s going to need to cut.

“I’ve shown some of the professionals in the area and they’ve already told me that I’ve got too many,” he said, laughing and recognizing he doesn’t want the window to turn into another decade-long project.

Looking forward, Parks said he’s thinking about making another lamp. He said he doesn’t think it will take as long. The hardest part will be finding the replica base for the lamp to sit on, but he said he wants to take on another challenge because he likes how the lamps make the glass shine.

“Without light, stained glass is pointless,” said Parks.

Chris Flood has been working for the Cape Gazette since early 2014. He currently covers Rehoboth Beach and Henlopen Acres, but has also covered Dewey Beach and the state government. He covers environmental stories, business stories and random stories on subjects he finds interesting, and he also writes a column called Choppin’ Wood that runs every other week. He’s a graduate of the University of Maine and the Landing School of Boat Building & Design.